MANST

Forschungsplatz 1

63820 Elsenfeld

Used to precisely control the distribution of the flow channel of the slurry, and regulate the flow size of the channel with "one out of four", "one out of six", "one out of eight" and other specifications to meet the needs of different customers to improve. Balanced system flow management, it is based on the flow dynamic algorithm, by adopting the diversion control management mode, so that the system flow is balanced management.

Adsorption of metal impurities in the slurry, improve the quality of the slurry using high magnetic materials, magnetic force ≥ 10,000 gauss, strong adsorption, efficient iron removal easy to disassemble, conducive to the regular cleaning of the iron remover using SUS304 material, corrosion resistance is good Magnetic bar outsourcing SUS316 material in series of 3 groups, a backup and a use of the online automatic switching, high production efficiency.

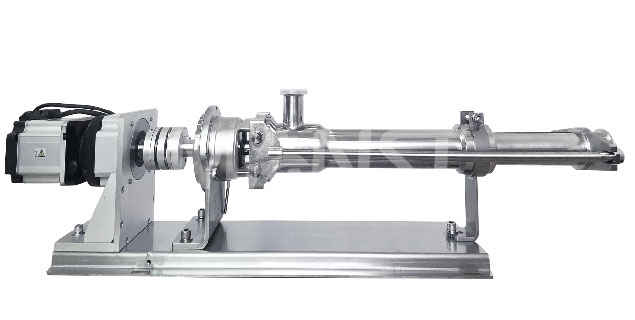

As the power element of slurry output, it provides stable power for the system to transport slurry with high manufacturing precision, can adapt to high viscosity, medium complex environment, corrosion resistance, simple structure, stable flow rate, small pulsation, high efficiency, easy to repair and maintenance.

Used for filtration of large particle impurities in the slurry to obtain high-quality slurry used in most of the high-speed production line conditions large filtration area, high filtration efficiency filter mesh specifications: 150 mesh, 200 mesh, etc. can be selected to meet the needs of different filtration precision structural design, no dead ends, thorough liquid discharge, no residual liquid filter monomer can be disassembled, easy to install and replace before and after the filtration is equipped with pressure monitoring, can be detected on the differential pressure.

Copyright © 2024 MANST Technology All rights reserved.