MANST

Forschungsplatz 1

63820 Elsenfeld

Filtering slurry flowing through pipelines using a mechanical dynamic filtration device

Meeting different filtration precision requirements with filters of different mesh sizes

Equipped with strong magnetic materials to effectively remove iron impurities from the slurry

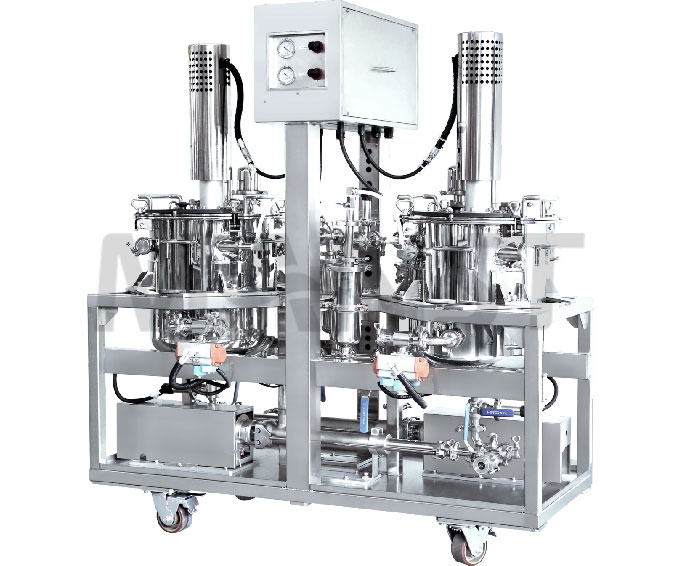

The slurry transport tank has functions such as liquid level detection, manual/auto feeding, viewing mirror window, interface reservation, and electric stirring. The slurry is transported steadily by a high-precision screw pump.

Slurry passes through a through-type metal mesh filter with bottom inlet and top outlet

Both filter units have pressure sensors at the common end. When the pressure difference reaches the set value, an alarm will prompt switching to bypass for cleaning the current filter element

A mass flow meter monitors parameters such as slurry temperature, density, flow rate, and viscosity

Equipment designed for single-layer adhesive application. The slurry is transported from the buffer tank to the iron remover and filter using a high-precision screw pump

The filtered slurry enters the diversion module through a constant pressure valve

Finally, it flows into the die head injection port via a switch valve

The equipment is suitable for single-layer coating

The coating slurry flows from the dynamic filter into the iron remover

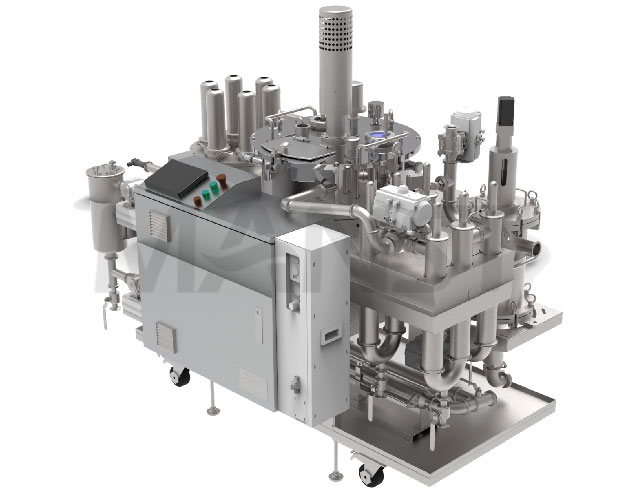

The slurry from the buffer tank is transported to the through-type metal mesh filter and cartridge filter by a high-precision screw pump

The filtered slurry finally flows into the die head inlet port through a flow meter

The equipment is suitable for dual-layer coating

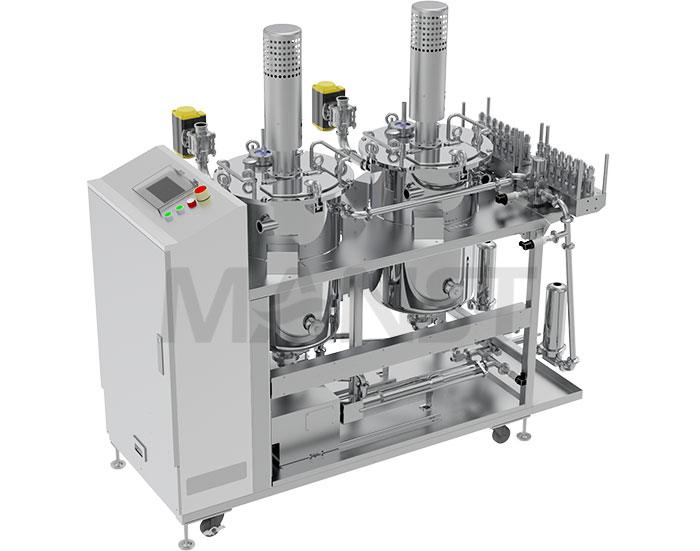

The slurry is transported from the buffer tank to the iron remover and filter using a high-precision screw pump.

The filtered slurry enters the diversion module through a constant pressure valve

Finally, it flows into the die head injection port via a coating switch valve

The equipment is suitable for dual-layer coating

The slurry flows from the dynamic filter into the iron remover

The slurry from the buffer tank is transported to the through-type metal mesh filter and cartridge filter using a high-precision screw pump

The filtered slurry flows into the die head inlet port through a flow meter

Copyright © 2024 MANST Technology All rights reserved.