MANST

Forschungsplatz 1

63820 Elsenfeld

High consistency in particle size distribution (D50 ≤ 10μm)

The internal spiral air flow in the tower is adjustable to meet changing requirements

Controlled removal of magnetic impurities

Energy-saving and environmentally friendly

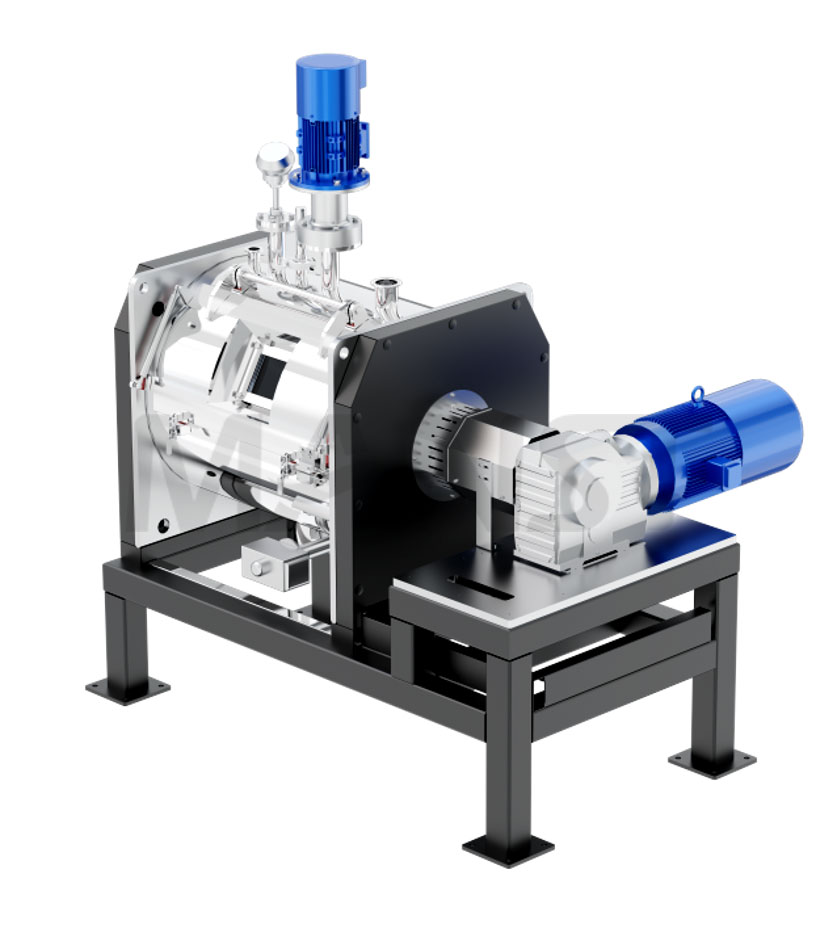

Single-shaft, multi-paddle design with high-speed flying cutter

Reliable sealing

Multiple sealing combinations to ensure chamber sealing

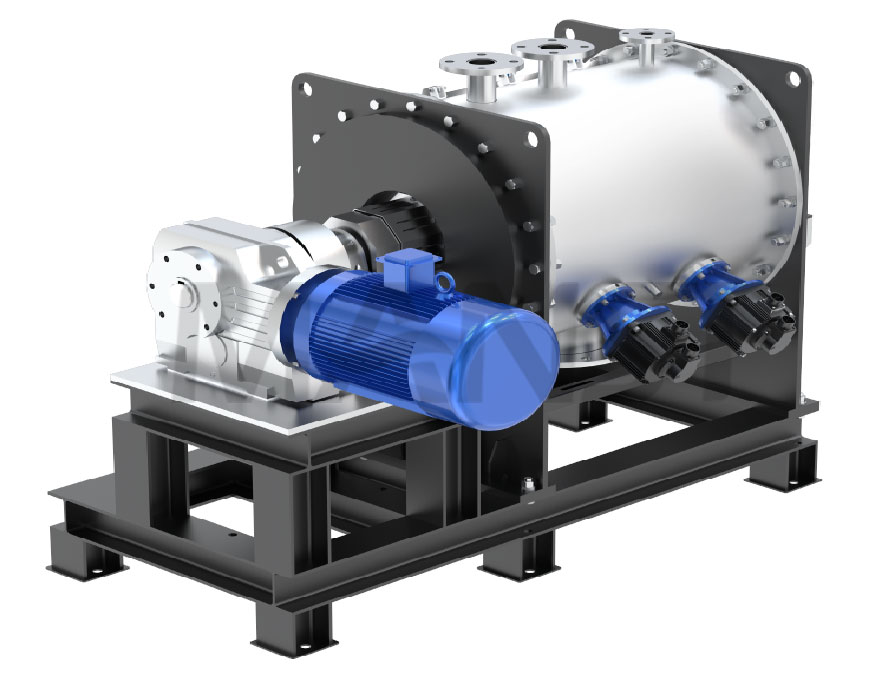

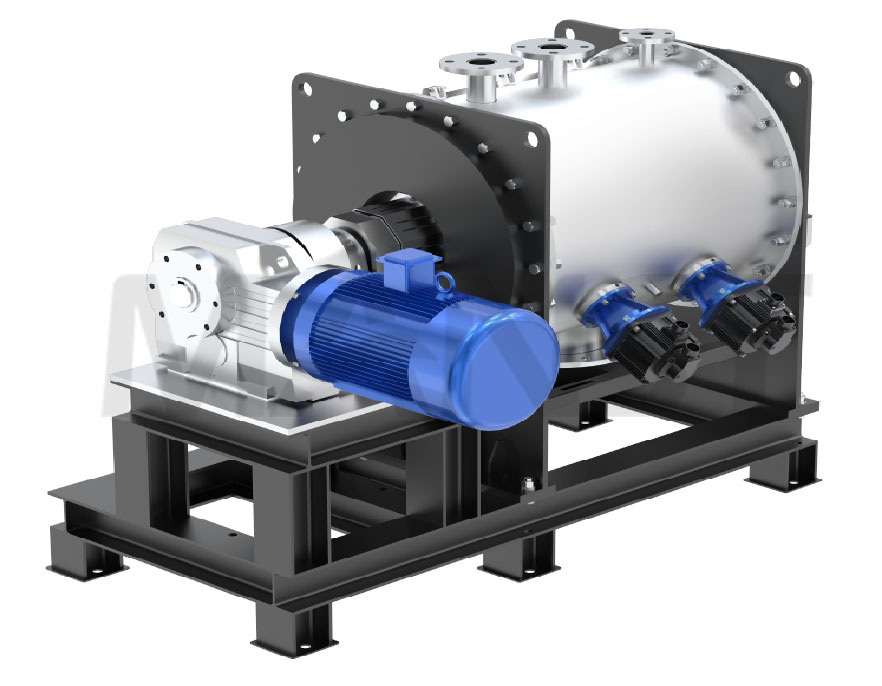

Adjustable working environment

Can operate under atmospheric pressure or vacuum; capable of heating or cooling

Wide range of applications

Suitable for powder blending and liquid-powder mixing

Powder Mixing

Liquid Mixing

Mixing of Powder with Liquid

Dispersion of Materials with Different Viscosities

High Packaging Accuracy

≤±0.1%

Fast Packaging Speed

5 to 20 bags per hour

Wide Range of Packaging Weights

300 to 2000 kg per bag

Adaptability

Easy Operation

Suitable for a Variety of Packaging Materials

High Mixing Efficiency

Single-shaft, multi-paddle design with high-speed flying cutter

Versatile Working Environment

Heating or cooling

Vacuum or atmospheric pressure

Wide Range of Applications

Powder mixing

Powder-liquid mixing

Mixing, dispersion, and coating of materials with different viscosities

Reliable Sealing

Multiple sealing combinations to ensure chamber integrity

High-Speed

≥400 rpm

High Shear

Optional high-speed flying cutter available

Working Environment

Not limited to: heating, cooling, vacuum, atmospheric pressure

Wide Range of Applications

Powder mixing, liquid-powder mixing, mixing, dispersion, and coating of materials with different viscosities

Copyright © 2024 MANST Technology All rights reserved.